PRODUCTS & SERVICES

We only use annealed wire in coil form to manufacture rivets, thus making the final riveting process hassle free. We undertake manufacturing of rivets to any specific requirement of customers precisely according to the drawings or sample rivets provided.

Solid and Semi-Tubular rivets can be completely customized as per the needs . The available metals, head-types and finishes are mentioned below.

Featured Services

The available metals, head-types and finishes are mentioned below.

Available Metals

- Mild Steel (MS)

- Aluminium (Al)

- Aluminium Alloy

- Copper (Cu)

- Brass

- Stainless Steel (SS)

Available Finishes

- Natural finish

- Trivalent Silver

- Copper Finish

- Nickel Finish

- Colour (RAL)

- Antique finish

Available – Head Types

- Flat head

- Round Head

- Oval Head

- CSK Head

- Pan head

- Headless Rivets

- Dimple on top

- Universal head

SOLID RIVETS

The solid rivet is the most widely used mechanical fastener in construction and manufacturing assembly. It offers the user these advantages:

- Its cost is low

- It allows high rate of production with minimal investment in machinery.

- It facilitates joining different materials of differing thicknesses.

- It has high shear strength.

- It is consistently applied by unskilled labor.

- It provides a tamper-resistant permanent joint

- It is versatile – can be structural yet decorative.

Below are examples of a few available head-types in Solid Rivets Available in : Mild Steel (MS), Stainless Steel (SS), Copper, Aluminum and Brass.

SEMI-TUBULAR(HOLLOW)RIVETS

Semi-tubular rivets (also known as hollow rivets) are similar to solid rivets, except they have a partial hole (opposite the head) at the tip. The purpose of this hole is to reduce the amount of force needed for application by rolling the tubular portion outward. The force needed to apply a semi-tubular rivet is about 1/4 of the amount needed to apply a solid rivet. Tubular rivets can also be used as pivot points (a joint where movement is preferred) since the swelling of the rivet is only at the tail. Solid rivets expand radially and generally fill the hole limiting movement.

Below are examples of a few available head-types in Solid Rivets Available in : Mild Steel (MS), Copper, Aluminum and Brass

- We provide hole depth as per the dimensions provided.

- If no details are provided then we manufacture rivets in accordance to the maximum hole depth as defined by Bureau of Indian Standards.

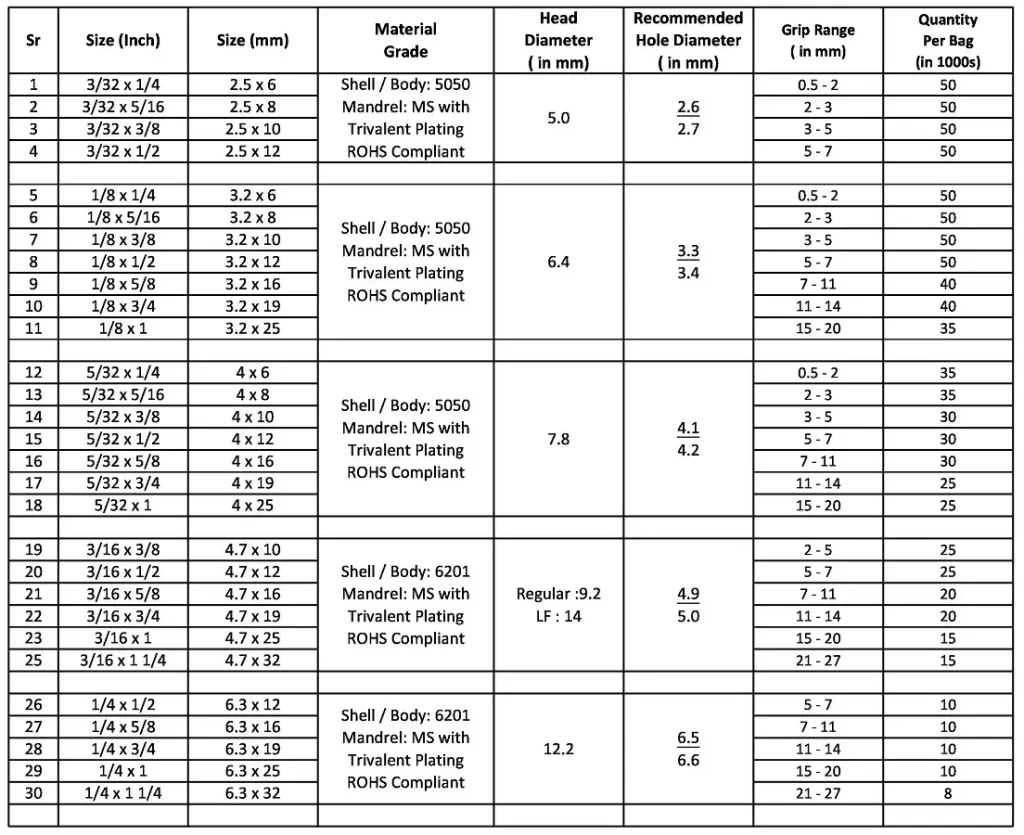

BLIND RIVETS (POP RIVETS)

Blind rivets, also known as pop rivets, are tubular and are supplied with a mandrel through the center.

The rivet assembly is inserted into a hole drilled through the parts to be joined and a specially designed tool is used to draw the mandrel into the rivet.

This expands the blind end of the rivet and then the mandrel snaps off.

These types of blind rivets have non-locking mandrels and are avoided for critical structural joints because the mandrels may fall out, due to vibration or other reasons, leaving a hollow rivet that will have a significantly lower load carrying capability than solid rivets.

Furthermore, because of the mandrel they are more prone to failure from corrosion and vibration.

Unlike solid rivets, blind rivets can be inserted and fully installed in a joint from only one side of a part or structure, “blind” to the opposite side.

TYPES OF BLIND RIVETS

We currently manufacture and supply rivets to a variety of industries and for various products

We Are Available For You, Call +91-9930223011, +91-9322287220